Nils Nietsch

Industrial Design Engineer with a passion for product design/engineering

About Me

Product design is the delicate balance between thousands of small details, all contributing to a bigger picture. It starts with a good idea and evolves to into many smaller studies on the mechanical, electrical, user experience, design, and manufacturability of the main idea. Its an iterative process that I and many other designers pride ourselves in. The the drive to create a valuable experience for oneself and others, is one of the cornerstones of human civilisation. Through learning and combining ideas from all sectors of industry we strive to develop novel ideas and products that inspire future generations.

My passion lies in blending beautiful design with functional mechanical, mechatronic, and electrical engineering. I enjoy working together with other engineers and stakeholders to find a balance in design and function. In my mind theres nothing more rewarding and fulfilling than developing a good idea from conception to production.

I was born in Breda and raised in California. I grew up in a small surfing town called Laguna Beach. After highschool I moved to the Netherlands and studied Industrial Design Engineering at the University of Twente.

My first acces to 3d printers and laser cutters was in high school. Ever since Iv been honing my design and production skills in all sorts of personal and client projects. Like many good engineers my foundation is set in legos and has evolved to projects such as, Opto-mechatronic systems, drone desigs, ebike builds, lighting designs, and smart home systems.

Curriculum Vitae

Work Experience

R&D Prototyping Service

Viridien and University of Twente

- Lead the technical development of a patented advanced sensing technology. Working together with Viridien’s management and software engineers as well as the University of Twente researchers and project managers.

Enschede, NL, 2023-2026Workshop Technician

DesignLab

- Run laser cutter and 3D printers (FDM, SLA)

- Teach others how to use workshop tools safely.

- Help students in building prototypes and provide solutions/advice.

Enschede, NL, 2022-2025Solidworks and Fusion 360 Teacher

University of Twente

- Help students learn CAD programs online and in person.

Enschede, NL, 2023-2025Engineering Intern

Cerno

- Worked on manufacturing/production improvements following lean practices.

- Designed and created drawings for parts in solidworks.

Managed ERP inventory using Sage 100.

- Created, updated and managed manufacturing stations.

Irvine, CA, USA, 2019

Education

Bsc Industrial Design Engineering

University of Twente (Enschede, NL)Bridge Year

Irvine Vally Collage (Irvine, CA, USA)High School

Laguna Beach High School (Laguna Beach, CA, USA)

Skills

SoftwareSolidWorks, Autodesk Fusion 360

Blender

OpenFoam

Adobe Illustrator, Procrerate

ArduPilot (Autonomous Drone)

EasyEDA (PCB Design)

Ansys Workbench

C, C++Hardware3D printing - FDM, SLA

Laser Cutting - CO2, Fiber

Lathe, Milling machine

Soldering

ESP32 and Raspberry PiInterpersonalMultidisciplinary environments

Collaborative

Adaptability

Results driven

Creativity

Portfolio

Developing Viridien's Advanced Spectral Imaging System

Designed and built an automated imaging system together with Viridien and a University of Twente research group. In this project I worked together with management and researchers to create a functional opto-mecatronic system to align a specialized laser and camera system. The contraption was ultimately patented (US12523529B2 and more) and is being tested at various sites across the globe. (Breif due to confidentiality)

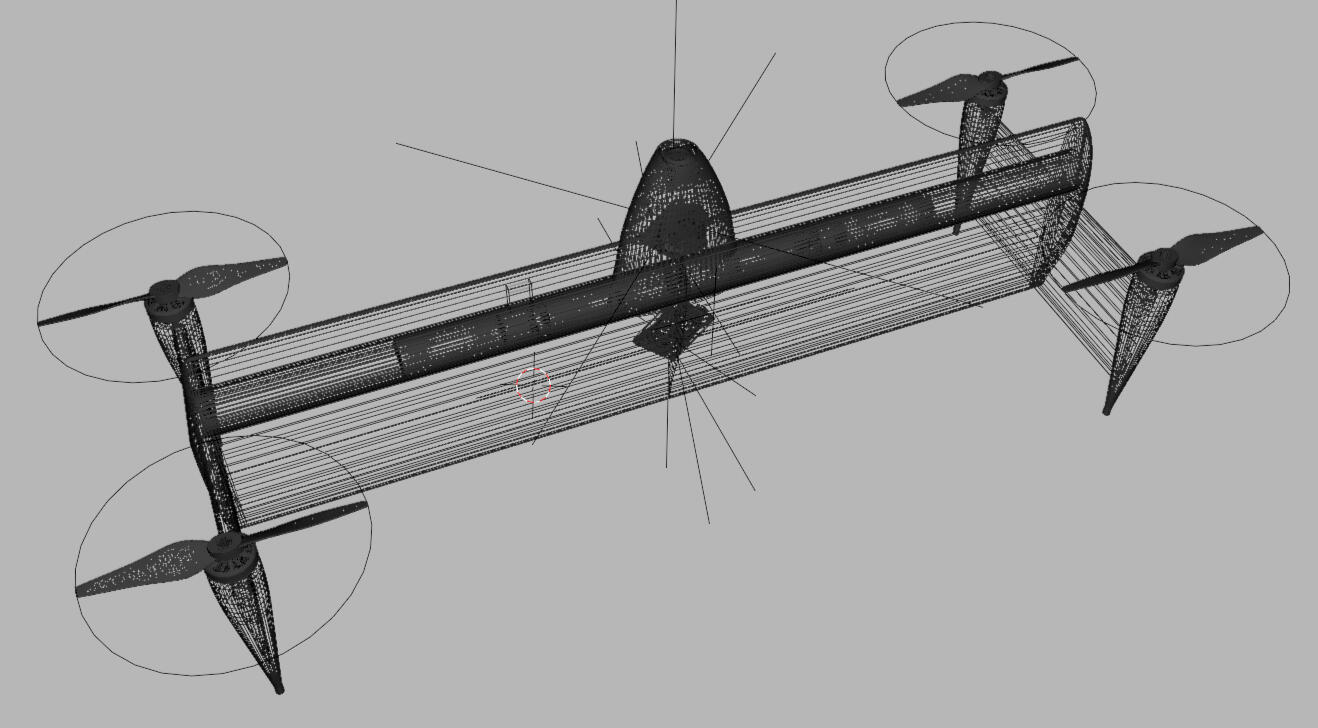

Lifting Body Drone (ongoing hobby project)

The idea behind the project was to create a vertical takeoff and landing UAV to explore mountains and valleys from the above. While also being able to survey land to create gaussian splatting 3D models.

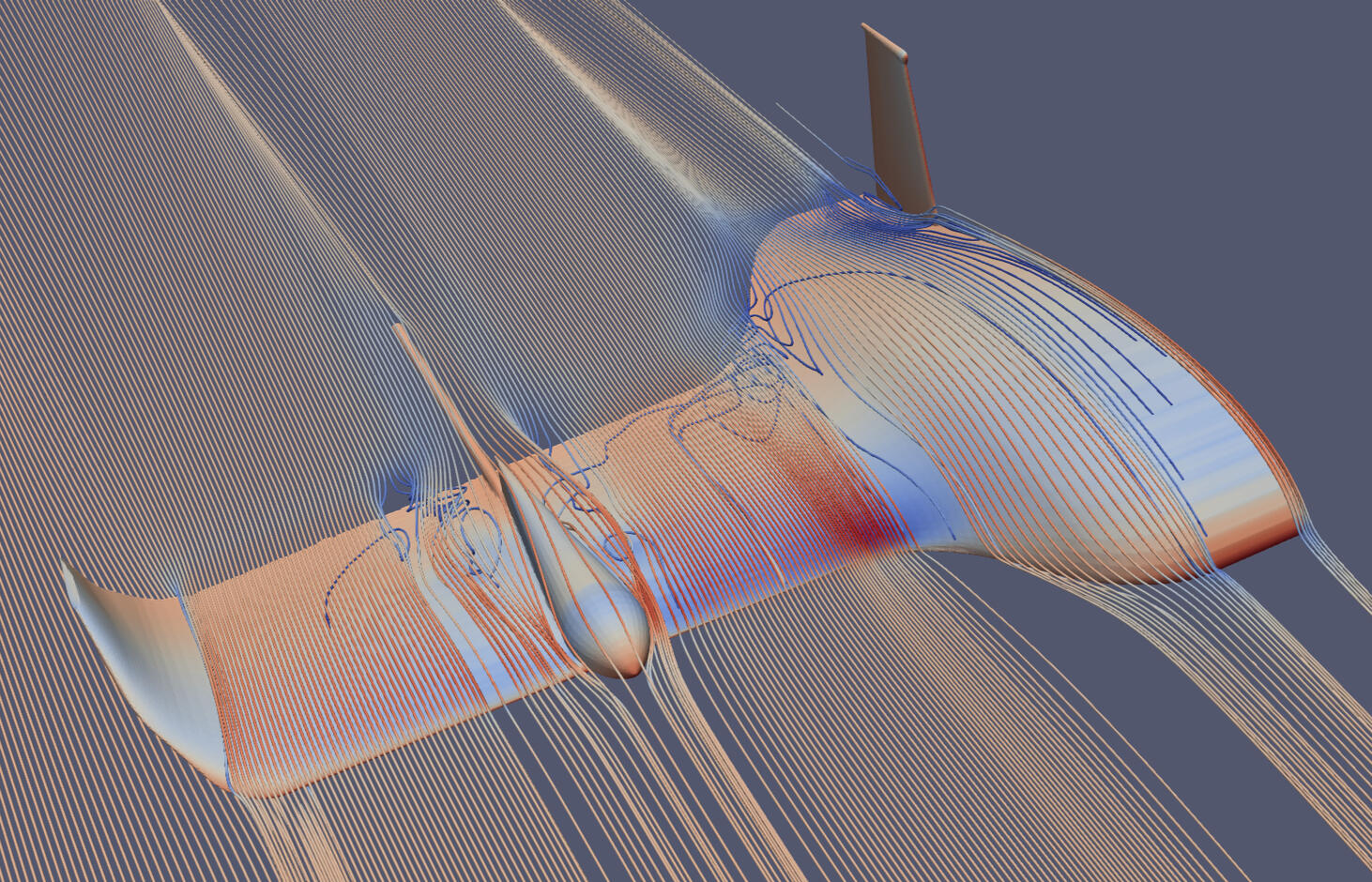

In this project I learned more about flying wings, autonomous control software and cfd simulation.

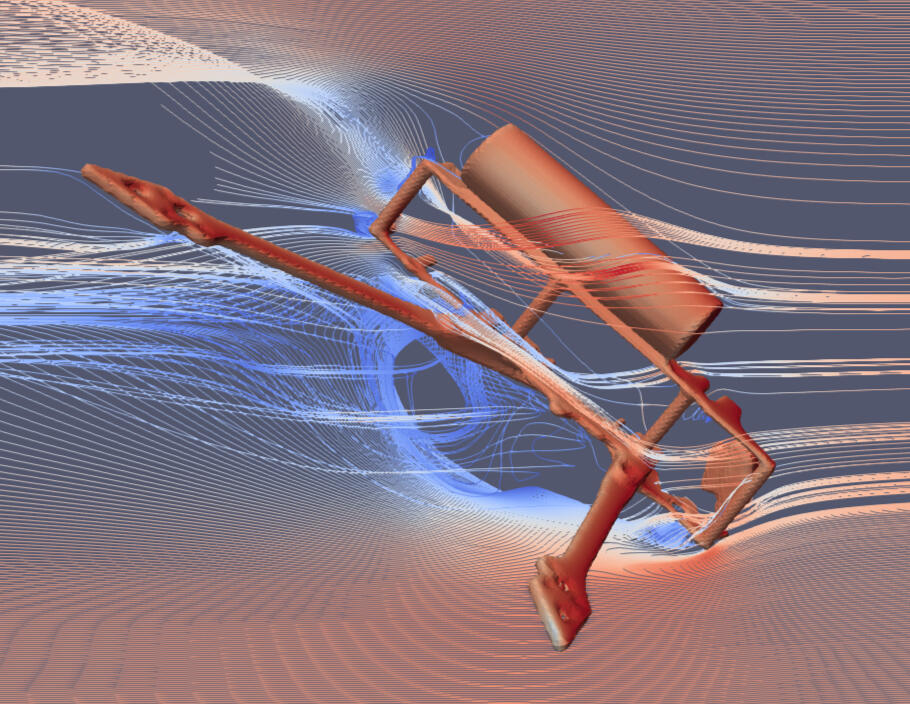

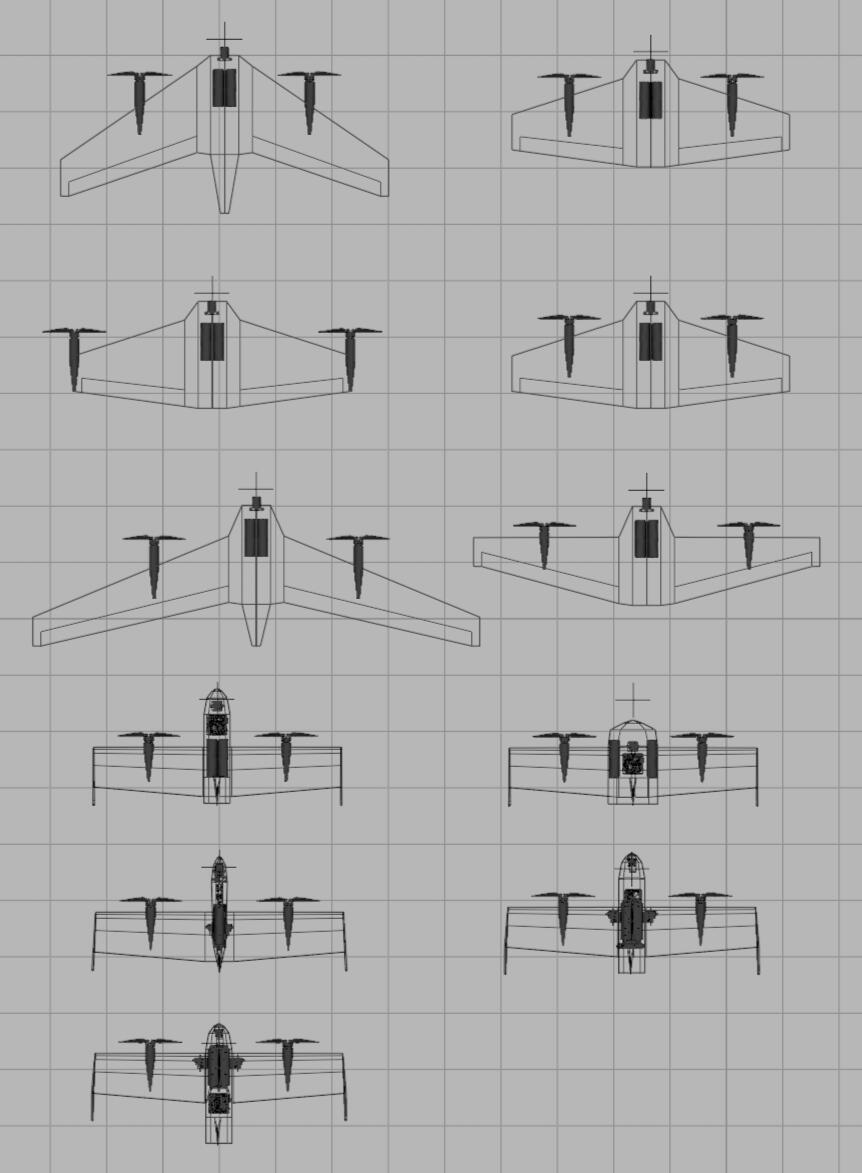

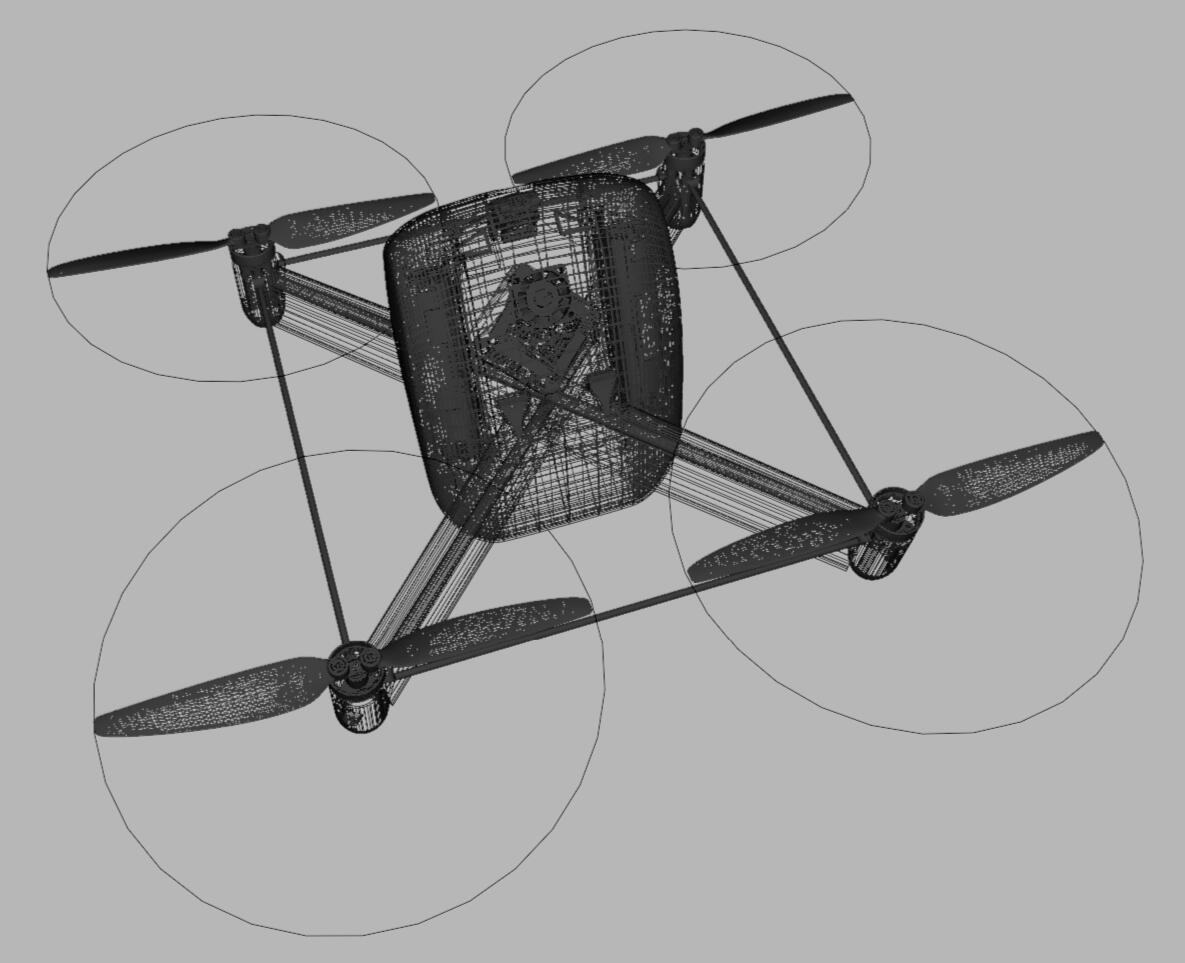

Generic fpv drones like the one seen in the CFD simulation above are not optimised for level forward flight. Rough simulation results suggest that at 60 kph the generic drone produces 40 grams force of downforce and 80 grams force of drag.Requirements were set, and an initial parts list was made. Based on this, I ideated various layouts of flying wings.

The idea behind the project was to create a vertical takeoff and landing UAV to explore mountains and valleys from the above. While also being able to survey land to create gaussian splatting 3D models.

In this project I learned more about flying wings, autonomous control software and cfd simulation.